What Is Stick Welding Used For

Equally you lot can probably imagine, stick welding isnot a uncomplicated topic — especially when nosotros start talking virtually selecting electrodes andall the dissimilar techniques you lot can implement. But non to worry, that's why we are bringing yous the ultimate guide to this fun and interesting topic.

In this commodity yous´ll learn everything nigh:

Basic overview of stick welding terms (SMAW), the required basic equipment and how stick welding works

What most the safety of welders, the pick of electrodes, the grooming of the joint, and the setting up of equipment?

The dissimilar stick welding techniques and basic guidelines for different metals.

What is Stick Welding?

If yous desire to become super-technical (and picky) here, then the proper term for stick welding is shielded metal arc welding or SMAW. The name "stick welding" is actually slang that came about in the community since information technology'southward a lot easier to say than the other.

However, stick welding is the most commonly used arc welding procedure, making apply of an electrode (sometimes called a filler rod or just a stick) and electric power to fuse metals together and fill up in the joint.

The electrode's cadre is made up of solid metal that is and then encased in mineral compounds and powdered metal , along with a bounden agent. It ensures the electrical current is conducted to the arcand that enough filler metallic is released for the joint.

As you might imagine, there are lots of different sizes andtypes of electrodes you tin choose from. The 1 you do decide to go with will define the arc'due south voltage and amperage requirements. Hence why this topic can be such a grey surface area — specially if yous're a beginner.

The Difference Between Stick, MIG and TIG Welding?

Mastering either ane of the three main types of welding can takeyears,lots of try, and buckets of equipment. So, you shouldprobably decide which to go with earlier you lot kickoff splashing the cash on your new workshop.

With that in mind, we'll expect at the differences hither so you can figure out whether stick welding is the i for y'all.

Stick Welding

If you are a direct-upwardly beginner or just want to have a fustigate at welding on the weekends, stick welding isdefinitely the one for y'all. Why? Considering information technology's the easiest method to larn (the basics tin exist covered in a single morning), requires less equipment, and is much cheaper than both MIG and TIG.

How Does Information technology Work?

- The car's negative cable is connected to your work so the power can travel through and make an arc when the electrode attaches.

- You but need to quickly touch the base of operations metal with an electrode and raise it slightly to create the arc.

- The electrode volition cook following this action and will fuse with the base of operations metal to create a "welding pool".

- In one case it has cooled downward, the articulation volition exist overnice and sturdy.

MIG Welding

Otherwise known as metallic inert gas welding, this process requires you to know a lot more nigh shielding gases and wire speed. Although, information technology's easier to get to grips with than TIG. Usually, setting up the machine is the hardest flake since the actual welding is relatively unproblematic.

How Does It Piece of work?

- You utilise a spool gun to push button the electrode out to make a weld pool. Here, the electrode isn't coated (like with stick welding).

- This is why y'all need to use shielding gases to protect the weld puddle.

TIG Welding

Depending on who y'all talk to, this is the hardest of them all. However, yous'll become fantastically precise and clean welds and so by and large, TIG is used for artwork and intricate pieces.

How Does It Piece of work?

- The electrode hither doesnon incorporate the filler material. Instead, it's made of tungsten that has an extremely high melting point.

- Yous'll have to utilize the filler separately from a "filler rod".

- In i hand, you'll agree the torch and in the other, you'll concord the filler. And then, yes, a lot of multi-tasking here.

I recently wrote an in-depth commodity on this subject, have a await at it: What´due south The Difference Betwixt TIG and MIG Welding?

Stick Welding: The Equipment

Equally we have already mentioned, stick welding is the simplest of all 3 primary methods. Thus, the equipment yous needed is decidedly uncomplicated also.

Related reading: Top five Essential Arc Welding Tools & Equipment List You Need

A stick welder contains four parts (all of which are necessary):

- A abiding voltage power supply (sometimes referred to as a CV ability supply or simply a stick welder)

- Ground clamp

- Slag removing tools

- Stick welding electrodes (i.due east. the rods to do the welding)

- Electrode holder

- Rubber equipment

At present, let'southward take a look at what each piece does, shall we?

Abiding Voltage Ability Supply

Manifestly, you can't start stick welding if you don't have a stick welder. There areand so many options available — you could even buy one that lets you perform all three welding methods! However, this will bepretty expensive so you're meliorate off simply buying a stick welder.

We'd recommend the Amico Power Stick Welder if you lot're a beginner.

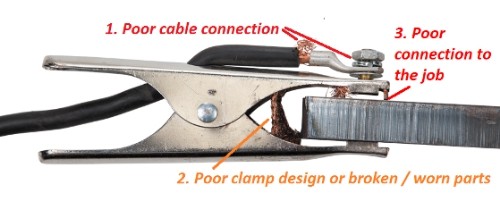

Ground Clench

Typically, this will come with the stick welder. You need to make sure that it is secure effectually your workpiece and is plugged directly into the stick welder.

Slag Removing Tools

Once you've finished welding, yous'll want to make clean off the slag. Our advice is to use a slag fleck and hammer before getting out your wire brush.

Stick Welding Electrodes

Y'all need to brand sure you selection the correct electrodes. But don't worry, we've got an entiresection about this further down to help you out with this confusing aspect.

Electrode Holder

Yup, this holds the electrode and stops yous from getting some pretty major injuries.

Safety Equipment

We're going to talk in-depth virtually condom equipment a scrap later on but for at present, simply know that youwill need it. That's correct, it'due south a not-negotiable.

I recently wrote an article on this subject, have a look at it: 30+ Must-Have Welding Tools & Accessories (Expert Poll)

So, How Much Does All of ThatPrice?

But like anything, information technology depends on what you're going to be using it for, the make you make up one's mind to go with, and your budget. There'due south no set in stone rule here and prices tend to fluctuate beyond the twelvemonth anyway. Regardless, we'll give you a petty overview!

For a great entry-level stick welder, you should expect to pay effectually $300. Alternatively, many companies offer a monthly financing option and then you don't have to drib that relatively big lump sum in one go. We would recommend choosing the Longevity Stick Weld 140.

Of course, as yous climb up the stick welder ladder, the prices go up. And when we say up we mean upwardly — all the way to $10,000 and beyond type of upwardly! Just don't worry, this tends to be for those who need it for huge industrial manufacturing andnot Joe down the road who likes to go in his workshop on a Sat.

Just be careful non to purchase whatsoever of thosereally cheap ones. Trust united states, you won't exist able to brand a quality articulation even if you're a world champion welder.

Related reading: Portable Welding Machine – v Things To Look For

How Long Will Information technology Take Me to Larn Stick Welding?

To tell you the truth, it depends on what you want to practise and how much you are willing to practise.

For general repairs around the yard, we would gauge that you could larn the nuts in roughly 5 hours .

Will your welds look great? Nope. Will they be pretty rough? Yes. But will they concur together and get the job done? Absolutely!

Notwithstanding, if you are looking to begin acareer as a welder, then you need to undertake a minimum of 500 training hours.

After that, to go an intermediate welder y'all must put in roughly 900 do hours. For a profitable pipe welding career, this will be much more than — most ii years of specialized training.

Related reading: Fast Way To Weld Similar a Pro – Fifty-fifty If You´re a Beginner!

What Materials Tin can I Work With?

Since you lot are now clearly very gear up on stick welding above the other options, nosotros demand to go over which materials you lot tin can work with here.

Subsequently you lot have purchased all the necessary equipment, you can become started on whatever of the following materials:

- Steel

- Cast fe

- Magnesium

- Stainless steel

- Nickel-based alloys

- Chrome

- Aluminum

Although we have put aluminum on here, information technology really isn't the best option. Withal, yous tin become the task done with stick welding.

You will need to make sure that your workpiece is rather thick since stick welding willruin thin, sheet-similar material. Generally, this method is fantastic for repairing tractors, working on farm equipment, power constitute structure, pipage welding, and utilizing metals that are over 1/16 inches thick.

Health and Personal Protective Equipment

Stick welding is dangerous enough as it iswithout the added trouble of non wearing the proper personal protective equipment. That's why ensuring you have purchased (and are wearing) the right garments isessential to making sure you accept fun and stay prophylactic while doing it.

And then, what exactly practice you lot demand? Let's dive into the details.

Eye and Confront Protection

When welding, the standard practice requires that y'all wear a combination of a helmet, goggles, paw shields, and condom glasses.

The exact eye protection y'all should be wearing depends on the specific task you're performing. Since this is quite a big topic, nosotros are only going to comprehend the basics here.

Related reading: How Long Does Welders Flash Burn Final? Symptoms and Treatments

Clear Lenses

These are great for protecting your eyes against impact. In this case, the bear upon could be caused by splashes, flying particles, or sparks.

Sometimes, y'all will need the safe glasses with side shields, only at other times you need goggles so they grade a seal around the entire eye. It all comes down to the job at home.

Welding Shades

As virtually people already know, the light that gets thrown around during the welding process is incredibly bright. No wonder retinal damage is a common trouble in the welding community, right?

That's why welding shades were invented. They make utilize of an extremely dark filter that lets you look at the arcsafely.

I recently wrote an article on this subject, have a look at information technology: What Do Welding Shade Number Mean? What About Condom?

OSHA (otherwise known every bit The Occupational Safety and Health Administration) set up out a regulation infographic that allows you to easily choose the correct filter depending on the task you lot're doing. To help you out, we've given yous the nuts of it below:

| Electrode Size one/32 Inch | Arc Current | Minimum Protective Shade |

|---|---|---|

| Beneath 3 | Under sixty | 7 |

| three to 5 | 60 to 160 | 8 |

| 5 to 8 | 161 to 250 | x |

| Over eight | 251 to 550 | 11 |

Information technology should be mentioned here withal that these shields rarely run into the guidelines for impact protection. You may demand to wear safety glasses underneath your face shield in this instance.

Helmets

More often than not, when nosotros talk about helmets in welding, we don't mean the bog-standard difficult hat that anybody on a construction site wears.

Instead, we are talking about those with extended neckpieces that protect your unabridged head, face, and (you guessed it) neck.

You can find those that take auto-concealment lenses, which allow yous to perform almost whatever welding project without needing to effigy out which glasses y'all need. Just let the helmet do it!

Related reading: How To Choose a Welding Helmet? What To Consider?

Clothing

Over again, the most appropriate clothing will vary depending on the specific job yous are doing. All the same, you should ensure you are wearing enough cloth to protect you from radiation burns, sparks, and splatters. Basically, your entire trunk should exist covered.

Yous should opt for night clothes that are made from either leather, wool, or incredibly thick cotton since they won't reflect low-cal from the under the helmet. Plus, the materials are durable which decreases the risk of them either melting or violent.

Another aspect we need to mention here is that you should not roll your sleeves up (regardless of how hot you go), nor should you gage your trousers. These rolls can catch clumsily hot debris that could seriously harm you.

Finally, youmust don flame-resistant gloves before you showtime. While you tin can get standard leather welding gloves, your best bet is to buy gauntlets equally these protect your unabridged arm.

How to Fix a Joint for Stick Welding

Unfortunately, you can't just turn on the machine and become to welding your joint. At that place is some training that you lot have to do to get your metal ready for the welding process.

We'll just dive right into the details since we'resure you don't want to read a load of waffle!

The kickoff thing y'all need to do is to make certain all the defects are removed. If you neglect this step, your weld won't be good, no matter how difficult you effort.

So, remove all the factory calibration, oxide, and rust. This is generally applicative to the metallic edge but but there is no impairment in doing your whole piece.

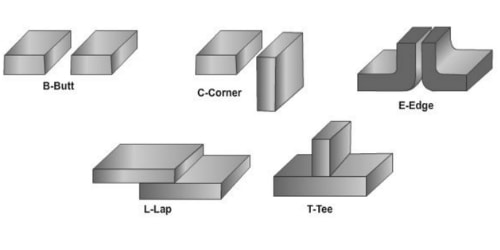

All of the to a higher place should be done regardless of what type of joint you are making. However, at that place are specific preparation steps y'all need to accept depending on the articulation kind. With that in heed, we volition take a look at each, ane by 1.

Acquire More About Welding Joints here: five Types Of Welding Joints and Their Use – Consummate Guide

Barrel Joint Prep

You lot can prepare this type of articulation in multiple ways namely, chipping, a flame, shearing, cutting, or a regular metallic grinder. Ordinarily, you will run into welders opting for the grinder as it's a less-hassle method.

For thinner metals, you will want to use a single 5 or single U groove joint. Just, for thicker materials, y'all should go with a double V or a double U articulation.

Edge Joint Prep

You might not exist doing so many edge joints with stick welding since this type of joint is usually used on incredibly sparse metals and, therefore, creates a weaker weld.

Having said this, yous tin can perform an edge joint with thicker materials for reinforcement only generally, salve information technology for thinner metals.

If you don't desire any bevels, then at that place is very fiddling in terms of preparation that you need to do. Just clean, tack, and weld! Merely in some circumstances, you volition need to bevel the edges to give you lot the all-time fusion.

Corner Joint Prep

You volition demand to decide whether you want a closed (where the metal is completely flush to each other prior to welding), half-open up, or full open corner joint hither.

Alternatively, you could perform a fillet weld corner joint but these tend to merely exist used for tanks and boxes.

Lap Joint Prep

While offset lap joints (there are plenty of images of these online if yous want to have a quick refresher of what they look like) are stronger, they tin be much harder to prepare. Why? Because the bevel you need to create is at an excruciatingly difficult angle.

Tee Joint Prep

You need to make sure yous bevel the correct edges when you're preparing to perform a tee joint. Then, tack weld it on each side before laying the bead.

Stick Welding Electrode Designations

This is the part that some of y'all will have been waiting for since the outset! Here, we are going to dive into the meanings behind electrode designations and how to select the correct i for the job.

So, let's get on with the meanings of the designations, shall we?

The designations on electrodes are the letters and numbers that are printed onto the outer blanket. The most widely used ones are E6010 and E7018.

When stick welding first became a "thing", the designation wouldalways showtime with an "E". Of course, this meant electrode. However, over the years this was dropped so yous will normally just notice numbers on them now.

Related reading: What is a 6011 Welding Rod Utilise for? What are The Advantages?

The beginning two digits tell you how strong the filler metallic inside the electrode is. Therefore, a 7018 electrode has a minimum of seventy,000 pounds of tensile strength per foursquare inch of weld. How do nosotros know this?

Because the first two numbers are 7 and 0! The weld is roughly twice as strong as the steel it is joining — quite astonishing when y'all think about it really.

The final half of the designation stands for the shielding on the electrode. The bigger the number is, the more shielding and/or metallic is emitted when yous're welding.

Thus, nosotros can tell that a 7018 has a lot more coating than a 6010 electrode.

Now that you understand what the designation really ways, we tin can move on to discussing which ones work best for unlike types of metallic.

Related reading: This is Why Welding Rods Need to Be Heated

Stick Steel Welding Electrode Choice

Beneath you tin notice the all-time electrodes for steel welding. Feel free to skip forth if steel isn't your preferred material!

| Designation | Used For | Position(southward) |

|---|---|---|

| 6010 | Deep penetration, good for "muddier" materials, peachy for open root welds | All |

| 6011 | Deep penetration, expert for "muddier" materials | All |

| 6013 | Medium penetration, must have a clean joint to work well | All |

| 7018 | Medium penetration, must be used with clay-complimentary metals | All |

| 7024 | Medium penetration, must accept a clean joint to work well | Flat simply |

The almost popular ones hither tend to exist the 7018, 6013, and 6010. If yous want a full general welding electrode then the 6013 is a no brainer choice!

Stick Stainless Steel Welding Electrode Selection

When y'all piece of work with stainless steel, the course of metal yous are welding will play ahuge role in the ane you decide to pick. While there are more 2 electrodes y'all can use, we will cover the ii principal ones equally we'll be here forever otherwise!

The 308L electrode is the most common one amongst welders who work with stainless steel. Information technology tin can be used on 304-grade stainless steel.

Alternatively, yous could use the 309L electrode which can be used when you work with regular steel. Ultimately, it is up for you lot to decide which one you prefer.

Related: Practise Welding Electrodes Accept a Shelf Life? Electrodes Expiry

Stick Aluminum Welding Electrode Selection

As we said earlier, stick welding aluminum isn't the best option. If you want to give it a go anyhow, just make sure that your workpiece is thick so it can withstand the welder metal.

You should utilise a 4043 electrode since you can weld in vertical, flat, and horizontal positions. Simply acquit in mind that you're request for trouble if you lot're aluminum is less than ⅛ inch thick.

Stick Welding Auto Gear up-Up

After you have selected your electrode (which the previous department would have helped you with), information technology is time to move on to setting up the machine. Of course, there are lots of ways to do this but we're but going to go over the basics for all you beginners out in that location.

Somewhere on your stick welder (unremarkably on the front), you will find two sockets. Your welder and electrode holder need to be plugged in here:

- Firstly, plug the stick welder in but do not turn it on. And so button the right stop of the electrode holder into the socket that has a plus sign on it. Make sure you twist information technology all the way.

- Afterwards that, grab your ground clench and make certain it is attached securely to your workpiece or your welding demote.

- In one case you've washed that, spiral the other finish of the table into the socket that has a minus sign next to it.

- Take hold of some scrap metal and heed to the crackle of the called-for electrode.

- Brand an arc and turn the power setting to melody into the right sound. If it resembles eggs frying in a pan then you take got information technology right.

The Stick Welding Techniques

Before yous starting time actually welding, you lot will desire to make sure you are comfy with the diverse techniques by practicing on some fleck metal. This style you tin can sort out the position of your hands and go used to the motions involved.

1. Hitting an Arc

Since this is pretty much the whole procedure, we'll first by looking at striking an arc.

Firstly, make sure the electrode is properly inserted into the electrode holder. So, turn the stick welder on.

The second step is to put the very tip of the electrode onto the metal. Then, yous will need to drag information technology incredibly quickly across information technology. Imagine that you are striking a lucifer — it's that sort of movement that you need.

One time the arc forms, you need to raise the tip a tiny chip and so you can maneuver it. If this is your showtime time, it's likely that the electrode has become stuck to the metallic. All you have to practice in this scenario is to twist it slightly to break information technology off and start again.

Related reading: Do You Button or Pull when Stick Welding? Which is Right?

2. Whipping the Electrode

If y'all are using electrodes that don't have a lot of flux, then you need to practise this whipping technique otherwise it volition get stuck in the weld.

Here, you use a back and forth motion that helps to get rid of contaminates. Bear in mind that it tends to be used on thinner materials, rather than the thicker stuff you might exist using with stick welding.

3. Circles

This one is fab for beginners.

Regardless of the electrode you are using, you can practice circular motions to control the speed of your motility across the join. On each circle, motility forrard slightly to travel over the articulation and you will accept fabricated a pretty not bad weld.

4. Weaving

Weaving is generally used on wide welds since it's easier to control. However, experienced welders like to use information technology with narrow joins besides considering they're more adept at minimizing their movements.

And then, how is it washed? Allow'due south take a look.

- Strike an arc as ever.

- Concur it to 1 side for a tiny bit.

- Move to the other side.

- Concur it at that place for a 2d.

- Repeat this motility until you have finished the join.

v. CLAMS

While this isn't a technique so to speak, itis an acronym that helps you remember what goes into making a great stick weld.

The "C" stands for Current (otherwise known as amperage). Setting this likewise loftier or too low volition result in a rough weld.

Related: What´south the Divergence Between AC and DC Welding?

The "L" stands for the length of the arc. Effort to keep it tight. This manner, you won't accept to bargain with it potentially going out or the electrode sticking to the plate.

The letter "A" refers to the angle of the electrode. We are near to talk near this (in the next section) since this does brand a difference to the quality of the final weld.

The letter "Yard" stands for the manipulation of the electrode . Depending on which designation you are using, you volition have to make circular motions (similar we said earlier) to command the travel speed.

The letter "S" refers to the speed of travel. The charge per unit at which yous movement will touch on the appearance of the bead, the undercut, and the heat input.

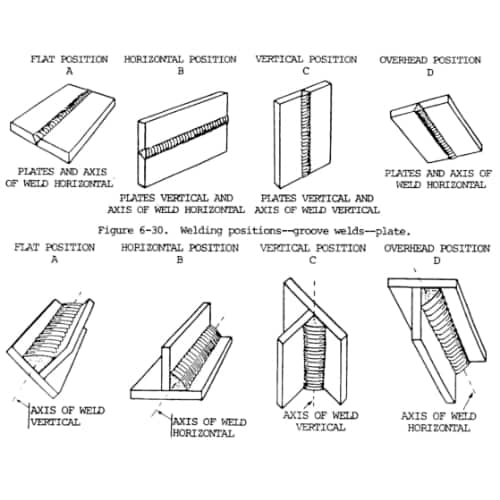

Stick Welding Rod Angles and Positions

To exist honest, as you get more than experienced, whatsoever angle volition practice just fine. Nonetheless, we are going to talk nigh the general rules that pretty much every beginner and/or intermediate welder tend to stick to.

Before you continue reading, here is an article I wrote nigh the four Master Welding Positions You Should Know – Complete Guide.

There will be some situations where welding at the "right" angle will be impossible. In these cases, you have no choice just to use an angle that isn'ttechnically "allowed".

At the end of the solar day, it will get second nature with plenty exercise. Anyhow, let'south get onto the standard guidelines.

Flat Welding Electrode Angle

When you are welding in the flat position, you should aim to move your electrode at well-nigh 10 to xxx degrees towards the join. If this sounds confusing, there are plenty of infographics online you can have a look at that draw it perfectly.

Vertical Welding Electrode Angle

Hither, it is easier to weld upwardly rather than downwards usually, but you practice any feels best. Regardless, you should agree the electrode at xc degrees to the metal being welded.

In other words, betoken it somewhere effectually thirty to 45 degrees to the bodily join.

Horizontal Electrode Angle

Gravity causes a lot of baloney with horizontal welding positions. You might want to bevel the edges here to hopefully command the weld pool better.

Hold the electrode at 90 degrees from the weld but make certain you are leaning into the management of travel by nearly xv degrees.

Overhead Electrode Angle

Substantially, overhead welding is the aforementioned as flat welding. So, you need to brand sure you are pointing your electrode in the movement direction by around 10 to 30 degrees.

Frequently Asked Questions

Can You Bear on the Rod While Stick Welding?

Can you lot touch the rod while stick welding? No, sorry, we know that was edgeless we merely needed to get information technology out there! Please, delight,please practisenot bear on the rod while you are stick welding. Y'all volition be on the receiving terminate of a nasty primary (and/or) secondary electric shock which isnot pleasant.

Every bit soon every bit the stick welder is plugged in, the electrode will become what is known as electrically hot. If you lot touch on it (or whatsoever of the other metal components in the stick welder), you will exist subject to a shock between 115 to 600 volts. This is the primary electric stupor.

The secondary i occurs if you touch a function of the electrode at the aforementioned fourth dimension every bit you lot touch the metal you are working on. Information technology is true that this is weaker than the main shock merely it withalreally hurts.

To avoid this, don't let whatever moisture habiliment near your welder, nor let your skin come into contact with it.

How Thick Tin a Stick Welder Weld?

If you accept purchased a 225 to 300 amp stick welder then it can handle pretty much whatsoeverthickness you will come across. Typically, yous only need most 200 amps to stick weld and so your auto will definitely exist able to handle the heat (for want of a better phrase).

How thick tin can a stick welder weld? The previously mentioned stick welder can weld material that is nether ⅜ inch thick in a single pass. However, if you are looking to weld thicker material, all you take to do is make multiple passes. This is what professional welders do!

To tell you the truth, yous are better off focusing on picking out the correct electrode for the task at manus since your stick welder is almost guaranteed to handle the thickness you are wanting to piece of work with. With that in mind, nosotros will chat a flake virtually the rods you should use on regular steel.

The Best Electrodes For Regular Steel

What are the best electrodes for regular steel? Welders tend to opt for one of the following electrodes when working with steel:

- 6010

- 6011

- 6013

- 7018

- 7024

Equally y'all probably know, each type of electrode has a certain ready of qualities that volition affect your thoughts on choosing it. To make it as piece of cake, nosotros have set out everything you need to know in the table below:

| Electrode Designation | Properties |

|---|---|

| 6010 | These penetrate very deeply. |

| 6011 | These penetrate securely and are great for welding in all positions. |

| 6013 | These penetrate less than the to a higher place 6010 electrodes. |

| 7018 | These produce a fantastic-looking bead. They are amend used when working with sturdier steel.due south |

| 7024 | These are the easiest to use. They keep the arc length at a constant so you can elevate more than effectively. |

Tin can Stainless Steel Be Welded With a Stick Welder?

Can stainless steel be welded with a stick welder? The brusque respond is yep, yous can weld stainless steel with a stick welder. If that was all you were looking for so you are adept to go! Just for those of you lot who want a bit more data on this matter, let's proceed.

We hear a lot of people request this question, simply it brings up an even more important one — should you weld stainless steel with a stick welder? To be honest, it depends on your level of skill, how you desire the last piece to await, how thick the stainless steel is, your budget, and the timescale of the projection.

If you are wanting a flawless, creative piece then you aremuch improve off TIG welding your projection. If you are wanting the job done and dusted with speed and effectivity, then MIG welding is for yous. But if you are just looking for a general weld, then you tin can't get wrong with stick welding.

Don't stress, we are going to delve into the actual pros and cons of using each method on stainless steel so you can brand a properly informed decision.

The Pros and Cons of Stick Welding Stainless Steel

The Pros

- It isn't any harder than welding steel.

- Rods run smoothly.

The Cons

- It is not great for decorative welds.

- Slag removal can be pretty unsafe as information technology flies off. Remember to continue your visor down until the chore is done!

Pros and Cons of TIG Welding Stainless Steel

Pros

- You get a lot of command.

- The quality is amazing.

- Fantastic for decorative pieces.

- Yous can erase distortion as you accept so much control.

Cons

- It is incredibly deadening.

The Pros and Cons of MIG Welding Stainless Steel

The Pros

- Incredibly quick to do.

- It is no harder than welding steel.

- You don't have to change your machine's settings.

The Cons

- In that location tin can be a lot of baloney since there you do not accept as much control.

- It isn't great for producing creative, decorative welded pieces.

What Welding Rod Is Used for Stainless Steel?

What welding rod is used for stainless steel? You should opt for a 209 or 213 shielded metal arc welding electrode when you are looking to weld stainless steel. They provide amazing strength and are fantastically durable confronting cracks. All the same, it is not always that elementary (you should know that welding is a pretty comprehensive topic by now!).

To be able to choose the correct electrode for stainless steel, we outset demand to await at theblazon of stainless steel you lot are going to be working with. Let's practise that now.

Stainless Steel: The Types

In all honesty, there areso many types of stainless steel that we would exist hereforever if we tried to mention all of them. So, we will stick to the ii that yous are most likely to come up into contact with.

The first ane is 304-grade stainless steel. Without a doubt, this is the variety you run into most. It is used for pretty much anything and can be welded with 308 electrodes.

Secondly, there is 316-grade stainless steel. This is mostly constitute in food preparation zones like industrial kitchens and such. You can employ 316 welding rods for this 1.

The Rule for Pairing Stainless Steel with Electrodes

You need to weld using the same grade of welding rod or higher. Yous are likely wondering what on globe this actually means. Are nosotros right? Idea so! Don't worry, we are about to shed some light on the matter by providing you some examples. Run across below:

- It's fine to weld 304-course stainless steel with a 308 or 316 electrode.

- It isnot fine to weld 316-grade stainless steel with a 308 electrode.

At last, it makes sense!

Do you Stick Weld Upward or Downward?

Do yous stick weld up or down? While you can practise both, experienced stick welders generally choose to weld vertically upwards (even though it is slower than the downwards technique) unless the cloth they are working on is very thin. Gravity will indeed piece of work confronting y'all when welding vertically (in both up or downwards methods) only there are some tricks yous tin implement to assistance you.

Permit's take a look at them, shall we?

Get The Correct Electrode

Finding an electrode with a 7018 designation is a expert place to start when stick welding upwards. They take a sufficiently low atomic number 26 powder content, which results in a weld pool that dries speedily and doesn't baste during the process.

Alternatively, you could utilize a 6010 electrode. Just acquit in heed that you lot won't be able to employ a weaving technique here. Instead, y'all will need to opt for a whipping or stacking method. Not to mention that it takes far more skill than simply using a 7018 electrode. But it's ultimately your choice.

Brand a Weld Shelf

Even though you have chosen the right electrode, gravity isn't going to become away entirely. Then, you demand to somehow finish your weld pool from spilling over.

This is where a weldshelf comes into play.

The fox here is to imagine your bricklaying. Yes, seems like an odd comparison only, trust us, information technology works. Essentially, y'all demand to ensure that every layer below the one you are working on acts equally a base.

To do this, goslowly. Create welds from the bottom of the piece upwardly, making i tiny chip at a time. Endeavor to ensure that each "shelf" is roughly 1 ½ timesbigger than your electrode'south diameter. This way, information technology will freeze in time to hold your adjacent weld in place.

Is Stick Welding Electrode Positive or Negative?

Polarity of stick welding, is stick welding positive or negative? Unfortunately, there isn't really a straightforward answer here. It is about understanding polarity because there are so many factors that come into play when deciding whether you should be stick welding with a positive or negative electrode setting. And then, nosotros volition talk about polarity hither to help you effigy out which yous should be using.

Air-conditioning and DC

Air-conditioning (or alternating electric current) and DC (or directly current) describe the electrical current that the welder ignites (so to speak) and the electrode conducts.

As you have probably already gathered, choosing the correct setting for your electrode will touch on how your weld turns out. Therefore, as nosotros briefly mentioned, yous need to empathise polarity to answer your initial question.

Read What´southward the Difference Between Ac and DC Welding to learn more.

You will hear the terms "reverse" and "straight" uttered among experienced welders which merely mean "electrode positive" and "electrode negative" polarity.

This polarity (a word you may well be sick of by the end of this) comes from the positive and negative poles of the electrical circuit fabricated by the welder and your electrode.

Direct current travels in a unmarried direction, which offers consistent polarity, whereas alternating electric current travels in a single direction 50% of the time and the opposite direction the other l%. This results in a changing polarity.

Generally speaking, electrode positive polarity gives you a deeper weld penetration and electrode negative polarity gives you a quicker electrode melt-off.

However, there are other factors that play into how well the aforementioned "rule" applies. For case, certain electrode coatings can change the effect. Typically, you should use a mild-steel electrode covered with high-cellulose for positive polarity welding. But once again, this doesn'talways utilize.

So, Which Do I Demand?

Usually, the electrode manufacturer's packaging will tell y'all exactly which polarity to employ. Alongside this, your stick welder should have each of the terminals marked and so you tin can see how to utilize it properly. If yours doesn't, then it might have a switch that allows y'all to hands modify the polarity.

How Much Do Stick Welders Brand a Year?

The average yearly salary for welders across the whole of the The states of America is just over $xl,000. In fact, this is higher than most other industries in the country! Being a welder is pretty lucrative if money is what you are looking for (you should probably be doing it for the love of the craft, of grade).

It is incredibly unlikely that you will start off in a stick welding position that pays $forty,000 a year. If yous do, and so congratulations, you are an anomaly.

How much practice stick welders brand a year? Y'all should expect to be paid around $xv to $19 per hour, meaning that your annual makings will be roughly $31,000.

Yet, it should be noted that it isnot an easy job. Information technology is probable that you will exist in pretty uncomfortable working environments. Plus, the hours can more often than not be quite long when compared with a 9 to 5 "desk chore". Not to mention the early on mornings and the intense heat that youwill exist subjected to every unmarried day.

Highest Paying States

Us that tend to pay the highest salary for stick welders are Wyoming, Alaska, Washington, Hawaii, Colorado, Due north Dakota, and New Mexico. These tend to be pipe welding jobs that are required to motility oil from i region to the next, which is why these states pay welders in betwixt $l,000 and $67,000. Information technology all depends on what sort of welding yous are looking to do.

STICK WELDING 101: Getting Started with SMAW >> Cheque out the video beneath:

References

https://world wide web.weldingtipsandtricks.com/stick-welding-techniques.html

https://www.praxairusa.com/about-us/frequently-asked-questions/what-is-stick-welding

https://world wide web.industrialmetalsupply.com/blog/what-metals-can-be-welded/

https://www.ishn.com/articles/108490-know-your-welding-personal-protective-equipment-ppe

https://www.arcweldingservices.co.uk/the-ppe-required-for-the-welding-process

https://world wide web.thefabricator.com/thefabricator/commodity/safety/selecting-the-best-lens-for-welders-eye-protection

https://www.wcwelding.com/joint-training.html#:~:text=The%20First%20Step%20To%20Joint,make%20it%20ugly%20and%20weak.

https://www.instructables.com/id/How-To-Stick-Weld-Basic-Guide/

Here are some of my favorite tools & equipment´southward

Cheers for reading this article. I promise it helps you find the nigh recent and authentic information for your welding project. Here are some tools that I employ daily and hope you´ll also notice helpful.

There are affiliate links, so if you practise decide to use whatever of them, I´ll earn a small commission. But in all honesty, these are the verbal tools that I utilise and recommend to everyone, fifty-fifty my own family unit. (NO CRAP)

To see all my of most up-to-date recommendations, bank check out this resource that I fabricated for you!

Best Overall

What Is Stick Welding Used For,

Source: https://weldingtroop.com/stick-welding-smaw/

Posted by: johnsoncrivair.blogspot.com

0 Response to "What Is Stick Welding Used For"

Post a Comment